Frequently Asked Questions

The unique formed in radius design used in manufacturing RimPro-Tec means that RimPro-Tecs are a universal fit on wheels ranging from 12" to 22".

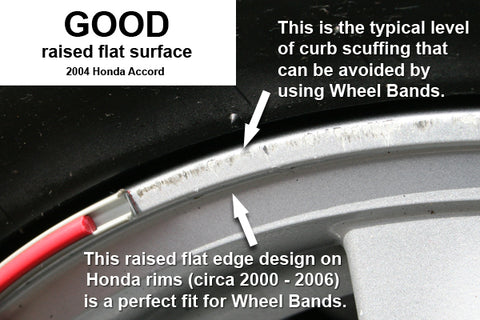

HOWEVER, PLEASE NOTE: The high bond adhesive tape used to attach RimPro-Tec to rims requires that there should be at least a 1/4" (6 mm) smooth, flat surface all the way around the wheel to mount the product properly to the wheel. RimPro-Tec should not be installed If your wheel design does not have an adequate smooth, flat surface required for proper mounting.

An An exception that can be made to the above requirement is if your rim design includes regularly spaced cutouts or narrow sections around the rim that are no more than 2" (50 mm) long. In this case, there does not have to be 100% attachment of the high bond adhesive tape all the way around the wheel. These designs perform well and are covered by our warranty. Example...

Below are examples of wheel designs that do not work with RimPro-Tec...

RimPro-Tec may be used to cover up lightly scratched and scuffed rims. However, their long term performance may be reduced. The damage should not be excessive or in a area more than 3" to 5" (125 mm) in length. If there is any raised up burr of metal in the damage it must be filed or ground down to flush with the rest of the wheel surface so that RimPro-Tec can be applied over it.

The photo below shows the typical amount of curb rash that may be avoided by or covered up by using RimPro-Tec.

RimPro-Tec are a defensive product intended to reduce the potential for scratches and light scuffs to your rims. A 5 MPH car bumper, they are intended to absorb some of the impact with road hazards in an effort to avoid more serious damage to what is behind them. The same as for your bumper, in many cases the RimPro-Tec will be damaged, but damage to the rims behind your RimPro-Tec will be reduced or avoided.

RimPro-Tec perform best in slow speed maneuvering conditions such as parallel parking and driving into car wash tracks. The best way to think of the value in using RimPro-Tec is like this: Without RimPro-Tec your bare rims are like riding a motorcycle with only a bathing suit on. With RimPro-Tec your rims are dressed in the equivalent of a leather jacket and leather pants — in the colors of your choice!

The current RimPro-Tec® system has been under development for over seven years. RimPro-Tec installed as long as seven years ago continue to perform without problem in real-life installations. Performance testing indicates that undamaged RimPro-Tec should commonly last for up to 40,000 miles. However, RimPro-Tec should be considered a wear item like a wiper blade. We recommend that they be replaced whenever you replace your worn tires. Color inserts can be taken out in seconds turned over and re-inserted to increase their full color life, or new color inserts may be purchased separately. It is not necessary to replace undamaged black or silver mounting trac.

RimPro-Tec behave like an adhesive tape version of Velcro™. Like Velcro™ (or like trying to slide a screen protector sideways) RimPro-Tec hold firm to the wheel while driving at maximum vehicle speeds but can be released from the wheel by prying straight up. To remove, locate the joint ends of the mounting tracks. Starting from the end joint, slowly pull the mounting track straight up off the wheel. When done with patience on all OEM clear coat and painted wheel surfaces, most of all of the adhesive tape will remain attached to the mounting track. Any amount of adhesive tape residue remaining on the rim will be limited. It can be rubbed off gently by hand or with a clean cloth.

Yes. RimPro-Tec can stand up to repeated car washing.

Properly installed and securely fastened, RimPro-Tec do not come off under normal driving conditions. However, they are a wear item on your car. Periodically check the condition of your RimPro-Tec. Loose color inserts should be fully re-inserted. Damaged RimPro-Tec’s should be replaced in full or by spliced in the section that is damaged. It is recommended that RimPro-Tec be replaced when changing tires on your vehicle, or after 3 years of service life.

Care needs to be taken and the proper equipment used, RimPro-Tec can be damaged during tire changes. It is important to let your tire change technician know you have RimPro-Tec installed. Mention that if they use the same technique as when changing tires on "chrome clad" wheels the RimPro-Tec should be fine.

No. This has been checked many times. Properly installed RimPro-Tec are a precision product manufactured to tight tolerances. Their installation does not affect wheel balancing. They also do not interfere with or affect the wheel alignment process.

If the painted surface was done at a professional shop where the paint was properly applied to the wheel the adhesive in RimPro-Tec will not cause damage to the painted surface when removing. If the painted surface is a DIY it depends on surface preparation before painting and quality of paint used. If the paint is on the wheel at least as strong as from can of spray on Plasti Dip applied to a properly cleaned up surface then RimPro-Tecs are safe to apply over the paint.

In many cases RimPro-Tec can be installed to wheels with clip-on wheel balancing weights. The RimPro-Tec track design allows for cutting the track flush with either end of the wheel weight clip. The color insert can then be snapped into the track and bridged across the metal clip. See photo...

NOTE: On your next tire change ask your tire installer to use tape-on wheel balancing weights. Tape-on weights use the same adhesive technology as used in RimPro-Tec.

RimPro-Tec are produced with an OEM grade of exterior attachment tape same as supplied to car companies. The tape uses the same tape technology as used in tape-on wheel weights. RimPro-Tec are manufactured with this tape in a Michigan manufacturing plant certified to the international automotive manufacturing standard ISO TS 16949. The highest standard in the industry. Across several years of production we have not identified any defective tape in RimPro-Tec products.

While it is not impossible that RimPro-Tec could be found with defective tape we consider the possibility small. The most common cause for Wheel Bands not to stick to a wheel is insufficient surface cleaning prior to installation...especially if a tire shine product has recently been used.

Another possibly that could cause RimPro-Tec not to stick to a wheel is if the wheel has been treated with an aftermarket surface coating advertised as "high gloss", "easy cleanup" or "non-stick." Example of such coatings are Armor All, Opti-Coat.

Yes. Single RimPro-Tecs can be purchased on-line.

NOTE: Scuffed color inserts with scuffs that can't be polished out, can be snapped out, flipped over and reinserted with the undamaged side up.

A sharp set of pruning shears work best to make a good clean square cut. If these are not available, it is better to use a box cutter or score the RimPro-Tec with a sharp knife and snap off. Scissors and wire cutters will usually not give a good squared up professional looking cut.

The plastic coils in RimPro-Tec kits have at least 6 to 8 inches of extra length even when installing on a set of four 22" wheel sizes. Before installation, we recommend making a few sample cuts to practice your cutting technique and to make sure you are starting with a clean edge of plastic and adhesive tape.

RimPro-Tec are proudly made in Two countries New Zealand and in the U.S.A. in a manufacturing facility certified to the ISO/TS 16949 Quality Management System Standard for automotive parts production...the #1 quality standard in the automotive industry.

RimPro-Tec Retailers

Buy now in our store, or shop for RimPro-Tec at your favorite automotive accessories retailer